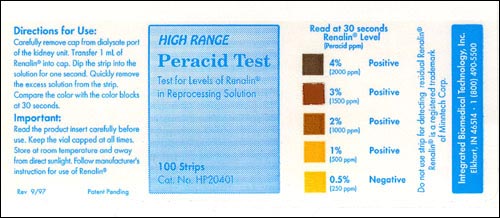

About the Test

The peroxide based disinfection solutions usually contain a mixture of peroxyacetic acid (peracetic acid or PAA) and hydrogen peroxide. Peracetic acid is a much stronger oxidant and is the main chemical for sterilization effect. Since peracetic acid is not stable, the solution also always contain high concentration of hydrogen peroxide and acetic acid to prevent peracetic acid from degrading. To test the true effectiveness of the sterilization solution, it is important that the test be specific to peracetic acid with minimal interference from the hydrogen peroxide. Peracid Test strip (HP20401) has a high specificity for peracetic acid. It is used as a potency test strip for peracetic acid based sterilant.

Product Features

1. Fast and easy to use.

- Dip and read the results in 30 seconds.

- No dilution of the concentrate sample is required.

- Easy to read color scales

2. More accurate

- Continuous color scale allow more accurate measurement of PAA concentrations.

- No confusing interpretation of results

- More reliable than qualitative pass/fail test

- Specific 1% color block prevent RO membrane from being damaged.

3. Long shelf life, stable at room temperature

- The dry strip is stable at room temperature.

- The shelf life is at least 3 years from the time of manufacturing.

Simple Steps to Use

- Collect the test sample in a clean cup.

- Dip the strip in the test solution for one second.

- For midstream sampling, wet the strip in the stream of test solution briefly.

- Gently shake off the excess water.

- At 30 seconds, compare the strip color to the color chart on the label and determine the peracetic acid concentration.

Some Specific Applications

Dialyzer reuse

Proper sterilizaton of the dialyzer is a key safety issue in dialyzer reuse and the key of the proper sterilization is to assure that a proper effective concentration of the peracetic acid solution is presence throughout the dialyzer cavities during sterilization. The difficulty, however, is that, with the physical constrains of the dialyzer structure, it is not possible to test and assure the true concentration of the peracetic acid solution inside the dialyzer fibers. Therefore, the solution at either the dialysate port or the blood port of the dialyzer is often used for testing.

There is a serious drawback with such a testing protocol. Since the contaminants of the dialyzer is mainly concentrated inside the holofiber of the dialyzer and much less in the dialysate side of the fiber, the dialysate port would be much less contaminated and, therefore, less demand for the peracetic acid and the peracetic acid is less consumed. As the result, the peracetic acid concentration at the dialysate port is expected to be higher. For the same reason, it is naturally expected that the peracetic acid concentration at the dialysate port be high and, lower at the blood port and even lower inside the blood side of the holofibers. The concentration of the peracetic acid tested at either the dialaysate port or the blood port is not the true representative of the peracetic acid concentration inside the dialyzer fiber.

One potential danger paused by such difference in concentration is that if the peracetic acid concentration at the blood port is mearly pass the Minimum Effective Concentration (MEC) of 500 ppm, the peracetic acid concentration inside the dialyzer fiber would certainly be far below the MEC concentration which is necessary for proper sterilization of the dialyzer. If the peracetic acid concentration inside the holofiber is to be maintained at a minimum of 500 ppm, it would required that the concentration at the blood port be maintained at a higher minimum concentration, for example, 1000 ppm. Such an assurance is not possible with the qualitative 500 ppm pass/fail test. With the Peracid Test strip, the peracetic acid concentration of 1000 ppm can be accurately measured. For the patients’ safety, monitoring of the peracetic acid concentration at 1000 ppm with the Peracid Test strip is highly recommended.

Disinfection of RO membrane

The chemistry of the polymer used in the RO membrane often contains sulfon or amide linkages which is susceptible to breakage by high concentration of peroxide. For safe disinfection of the RO membrane, the peracetic acid concentration is often adjusted to 500 ppm. If the concentration is too high, the peracetic acid may cause damage to the RO membrane. If the concentration is too low, on the other hand, the membrane may not be sufficiently disinfected. Accurate measurement of the peracetic acid at 500 ppm is critical. With the Peracid Test strip, peracetic acid at 500 ppm can be accurately measured. For safe operation of the RO system, the use of Peracid Test strip to verify the concentration of peracetic acid at 500 pmm is highly recommended.

Disinfection of dialysis machines and water piping systems

Although the exact concentration of the peracetic acid in such application is less critical, Maintaining the concentration above 500 ppm is important and desirable. The Peracid Test strip can help to maintain the proper concentration for optimal disinfection.

Ordering Information

Product Availability

The Peracid Test strips are packaged 100 strips in a bottle and 6 bottles in a box.

| Cat. No. | Description |

| HP20401 | Single bottle of 100 strips |

| HP20401-6 | 6 bt/pk (500 strips) |

Ordering Information

Order by phone, fax or email.

Contact our Customer Service for more information or technical support.

Customer Service:

Tel: 574-264-0025

1-800-490-5500

Fax: 574-264-2787

email: ibtbiomed@earthlink.net

R: ec102